Many friends who are in contact with and prepare to buy amphibious excavators for the first time have limited understanding of it. What should be paid attention to to avoid being fooled? The editor has sorted out the following for you to help you make better choices:

- The first choice is to confirm what type of amphibious excavator you need to buy

Our conventional amphibious excavators are three models of RS80/RS150/RS215, and other sizes of amphibious excavators can also be customized according to needs. When purchasing amphibious excavator for the first time, you need to combine your own construction environment and long-term needs, and learn from the business what types of construction conditions the corresponding model is suitable for.

- How to choose configuration

Generally, conventional amphibious excavator can work in silt and shallow water of about 1-1.5 meters without adding side floating pontoons. When it comes to deep water, it is necessary to add side floating pontoon installed on both sides of the pontoon undercarriage to increase the buoyancy of amphibious excavator. The floating side pontoon can be used as an option. If you don’t need it, just make it as an optional. You can also buy it later if you need it.

- The work scope for amphibious excavator

Because the pontoon undercarriage of amphibious excavator is much larger than the standard traditional excavator, the general working device of amphibious excavator, that is, the boom and forearm we call, will be lengthened. .

- Selection of walking hydraulic motor

Because the working environment of amphibious excavator is relatively harsh, relatively large power is required to facilitate construction. We recommend: according to the model of the excavator used, choose a relatively good motor brand in this level, or a larger model.

- Selection of the size of pontoon undercarriage

The size of the amphibious pontoons determines its buoyancy. This is a relatively reasonable size obtained after a long period of construction experience accumulation, actual working conditions, and customer market feedback. Not to say, the better or the smaller is better. Therefore, care must be taken in the selection of the size of the pontoon.

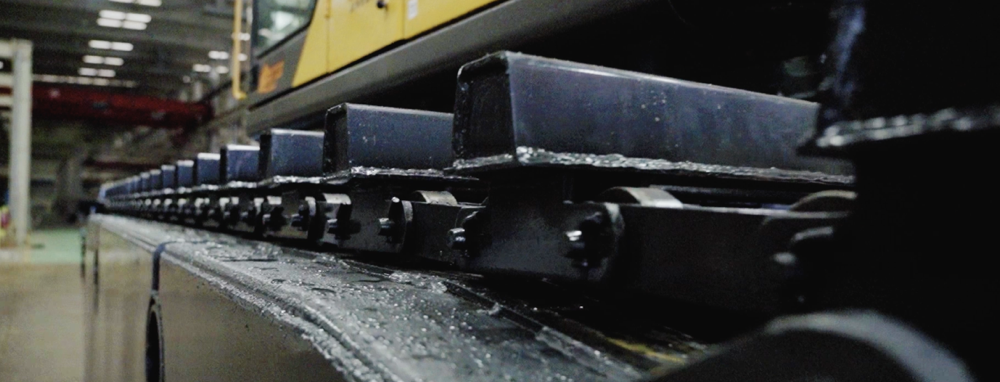

- Materials for several key parts

The material of the track shoe – all the weight of the whole vehicle will be on the track shoe. If the material is not good, it is very easy to deform, which will cause the chain to derail, and the impact on the construction is self-evident. Our company chooses HG785 high-strength steel as the chain plate material, which can effectively reduce the weight of the whole vehicle while improving the support strength of the tracks.

The quality of hydraulic oil pipes and oil pipe joints – low-quality oil pipes are easy to burst during the construction process, which is very troublesome to maintain, and will also bring significant economic losses.