LONG REACH BOOM

Extended Arm – Long Reach Boom For Excavator

River Heavy Industry (RHI) specializes in the design, production, and customization of long-reach boom, particularly adapted for various brands of hydraulic excavators, including those requiring long reach excavator. Our long reach boom ensures optimal performance and efficiency for specialized excavation needs

Jiangsu River Heavy Industry(RHI) is a prominent manufacturer and supplier of long-reach booms in China. We deliver premium-grade extended arms/sticks renowned for their durability and quality across global markets. Our comprehensive range includes excavators with extended boom spanning from 7 tons to 100 tons for crawler excavators, offering extended arm lengths ranging from 7 meters to 30 meters. We prioritize customization to align with our discerning clientele’s unique specifications and applications, ensuring optimal performance and satisfaction.

Technical Specificatinos of Our Long Reach Boom

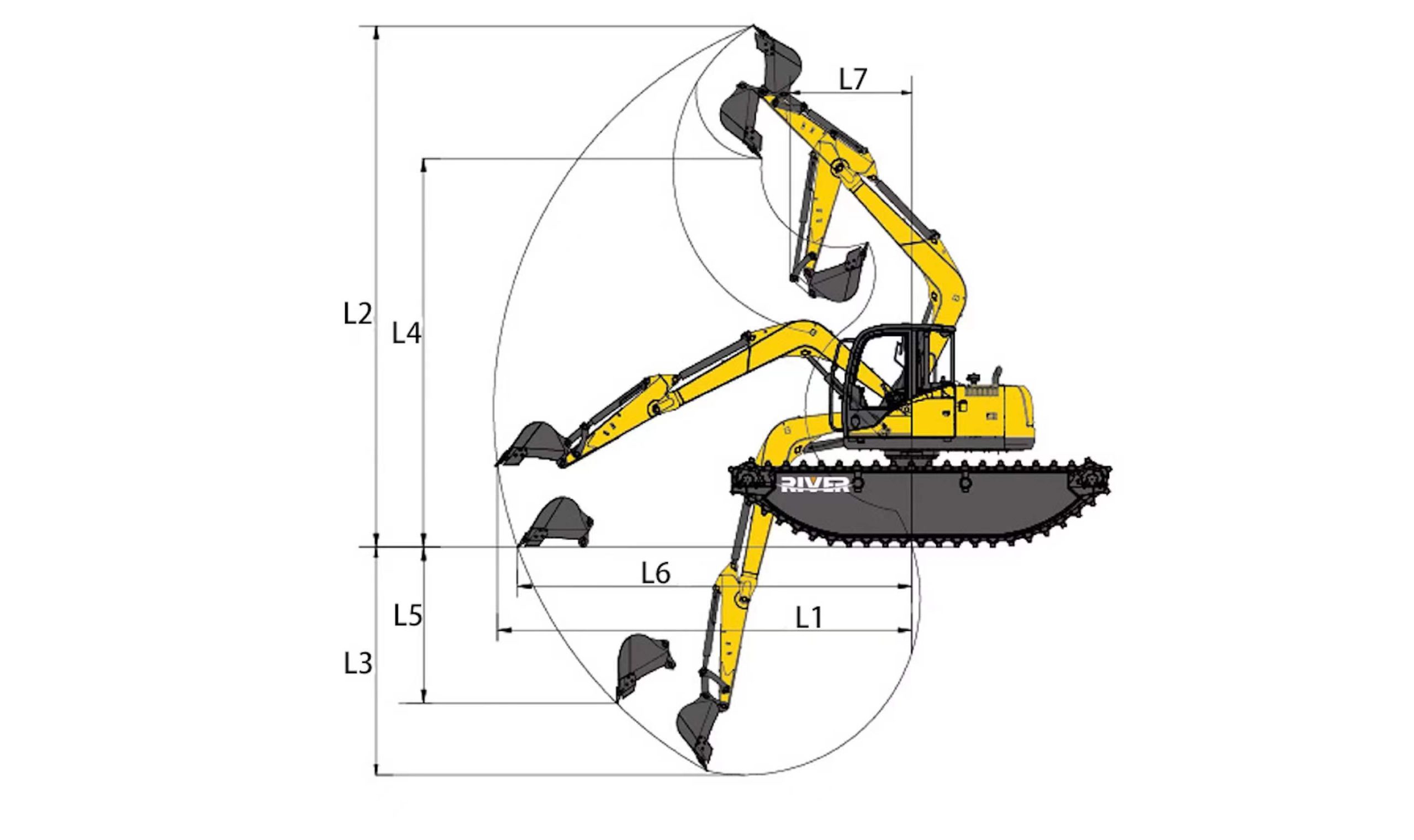

| Amphibious Excavator Operating Weight |

Total Length | Boom Length | Arm Length | Bucket Capcity | Max. Excavation Radius(L1) | Max. Unloading Height(L2) | Max. Excavation Height(L4) | Max. Excavation Depth(L3) | ||||

| m | ft | m | ft | m | ft | m³ | Yard³ | mm | mm | mm | mm | |

| 9-10 tons (Mounted with 7-8 tons Upper Car-body & RS80 Undercarriage) |

7 | 22.96 | 3.99 | 13.09 | 3.01 | 9.87 | 0.30 | 0.39 | 7780 | 7460 | 9180 | 4700 |

| 9 | 29.52 | 5.13 | 16.83 | 3.87 | 12.69 | 0.20 | 0.26 | 9780 | 9460 | 11180 | 6700 | |

| 19-21 tons (Mounted with 13-15 tons Upper Car-body & RS150 Undercarriage) |

9 | 29.52 | 5.13 | 16.83 | 3.87 | 12.69 | 0.60 | 0.78 | 10220 | 8870 | 11340 | 6305 |

| 11 | 36.08 | 6.27 | 20.57 | 4.73 | 15.51 | 0.50 | 0.65 | 12220 | 10870 | 13340 | 8305 | |

| 12.5 | 41 | 7.125 | 23.37 | 5.375 | 17.63 | 0.40 | 0.52 | 13263 | 11784 | 13846 | 8254 | |

| 28-33 tons (Mounted with 18-23 tons Upper Car-body & RS215 Undercarriage) |

11 | 36.08 | 6.27 | 20.57 | 4.73 | 15.51 | 0.80 | 1.04 | 12080 | 9915 | 12800 | 7815 |

| 13 | 42.64 | 7.41 | 24.30 | 5.59 | 18.34 | 0.60 | 0.78 | 14080 | 11915 | 14800 | 9815 | |

| 15 | 49.2 | 8.55 | 28.04 | 6.45 | 21.16 | 0.45 | 0.59 | 16080 | 13915 | 16800 | 11815 | |

| 17 | 55.76 | 9.69 | 31.78 | 7.31 | 23.98 | 0.40 | 0.52 | 18080 | 15915 | 18800 | 13815 | |

| 38-42 tons (Mounted with 27-33 tons Upper Car-body & RS300 Undercarriage) |

15 | 49.2 | 8.55 | 28.04 | 6.45 | 21.16 | 0.60 | 0.78 | 15350 | 14015 | 16925 | 11560 |

| 18 | 59.04 | 10.26 | 33.65 | 7.74 | 25.39 | 0.40 | 0.52 | 18350 | 17015 | 19925 | 14560 | |

| 20 | 65.6 | 11.4 | 37.39 | 8.6 | 28.21 | 0.30 | 0.39 | 20350 | 19015 | 21925 | 16560 | |

| 46-52 tons (Mounted with 34-37 tons Upper Car-body & RS350 Undercarriage) |

15 | 49.2 | 8.55 | 28.04 | 6.45 | 21.16 | 0.80 | 1.04 | 15800 | 10180 | 10860 | 9680 |

| 18 | 59.04 | 10.26 | 33.65 | 7.74 | 25.39 | 0.60 | 0.78 | 18800 | 13180 | 13860 | 12680 | |

| 20 | 65.6 | 11.4 | 37.39 | 8.6 | 28.21 | 0.40 | 0.52 | 20800 | 15180 | 15860 | 14680 | |

| 24 | 78.72 | 13.68 | 44.87 | 10.32 | 33.85 | 0.30 | 0.39 | 24500 | 19900 | 22300 | 16500 | |

| 57-62 tons (Mounted with 38-44 tons Upper Car-body & RS400 Undercarriage) |

15 | 49.2 | 8.55 | 28.04 | 6.45 | 21.16 | 1.00 | 1.30 | 15800 | 10180 | 10860 | 9680 |

| 18 | 59.04 | 10.26 | 33.65 | 7.74 | 25.39 | 0.80 | 1.04 | 18800 | 13180 | 13860 | 12680 | |

| 24 | 78.72 | 13.68 | 44.87 | 10.32 | 33.85 | 0.50 | 0.65 | 24800 | 19180 | 19860 | 18680 | |

| 30 | 98.4 | 17.1 | 56.09 | 12.9 | 42.31 | 0.40 | 0.52 | 30800 | 25180 | 25860 | 24680 | |

The long reach excavator boom length is tailored to your requirements, the models of excavator, and the customization options available. Explore quality long-reach booms with special sizes—contact us for customized options tailored to your unique project requirements!

Each Long Reach Package Comes Standard with The Following Items

Long reach boom is an excellent solution for river and sea dredging on land or barge, pond excavation and maintenance, deep foundation excavation, drainage construction, distant digging, etc., especially beneficial for slope forming where standard boom failed to get the necessary job done effectively. There is no customized component/part used in our attachment; we design it with commonly available off-the-shelf components that customers can easily obtain from their local excavator spare parts market. Each long-reach package includes:

Advantages of Our Long Reach Boom

Application of Excavator With Extended Boom

The extended arm is a staple in diverse construction applications, including river dredging, port operations, subway construction, and foundation excavation. Renowned for its exceptional efficiency and safety, it excels in a myriad of operations. When the standard arm falls short of reaching extended and deeper digging distances, the River-produced long reach boom emerges as a pivotal solution, enhancing productivity to meet the demands of challenging projects.

- Demolition and Construction: Ideal for high-reach demolition tasks, allowing for safe deconstruction of tall structures and buildings.

- Marine and Dredging Operations: Suitable for extended reach in dredging from land or barge, enabling efficient waterway maintenance and coastal projects.

- Mass Excavation: Offers greater reach for large-scale earthmoving operations, simplifying deep excavation tasks with buckets or clamshell attachments.

- Waterway Maintenance: Perfect for cleaning up lakes, rivers, and fish ponds by removing sediment and debris.

- Hydropower and Water Resources Projects: Supports excavation in water resource management and hydropower engineering works.

- Urban Construction: Effective for deep subway and tunnel excavation, allowing for precise and efficient digging in confined urban spaces.

How Does Long Boom Excavator Work?

Reliable Long Reach Boom Manufacturer – Why Choose RIVER?

RIVER offers a range of long reach booms for excavators, designed to fit different models and meet varying project requirements. With custom lengths available, these arms provide enhanced flexibility for hard-to-reach tasks. In addition, RIVER supplies hydraulic hydraulic dredging pumps and a selection of buckets to ensure complete project efficiency. Whether you need long reach boom for excavator or specialized equipment for your excavation projects, RIVER has the solution to get the job done.

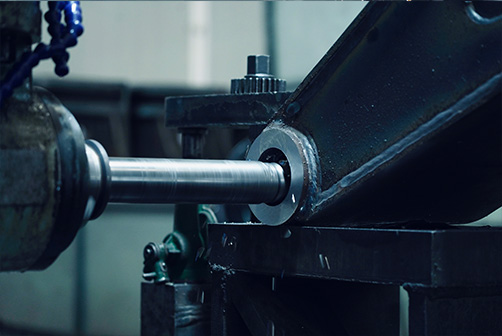

- Cutting-Edge Manufacturing and Processing Capabilities: As a distinguished Long Reach Boom manufacturer, we boast a comprehensive suite of advanced processing and manufacturing equipment, including laser cutters, plasma cutters, welding robots, and automatic coating lines. This arsenal ensures the precision of our products, guaranteeing both excellence and high production efficiency.

- Premium-Quality Raw Steel Materials: Our commitment to excellence extends to sourcing raw materials exclusively from China’s top steel manufacturers. The extension arm, crafted from low-alloy high-strength plates with commendable tensile strength, is pivotal for optimizing the efficiency of excavators. Notably, our hydraulic hoses undergo phosphating for superior anti-corrosion and anti-rust properties, safeguarding the hydraulic system from contaminants. The use of copper sleeves on connectors, in place of the commonly used steel sleeve, further underscores our dedication to quality.

- Advanced Computer-aided Design Tools: Employing state-of-the-art CAD, 3D, and FEA structural design tools, our adept design team provides accurate data analysis for secondary development and personalized customizations. This technological prowess not only facilitates product upgrades but also minimizes production timelines. Addressing concerns of potential cracking and breaking, our innovative designs prioritize the longevity and reliability of our long arms.

- Stringent Production Processes for Unwavering Quality: At every juncture of the production process, meticulous controls are implemented to guarantee the delivery of products of the highest quality. Our unwavering commitment to strict quality control ensures that our customers receive consistently reliable and top-tier products.

Contact us today to customize your long reach excavator arm and optimize your next project!

Finishing

Plasma Cutting

Robot Arm Weiding

Polishing

Machining

Spray Painting

FIND YOUR RIGHT SOLUTION WITH RIVER HEAVY INDUSTRY

At RIVER HEAVY INDUSTRY, we are committed to providing high-quality amphibious excavators and specialized excavator attachments. If you have any inquiries or would like to discuss your specific requirements, please fill out the form below. Your satisfaction is our top priority, and we guarantee prompt responses to clients around the world. We look forward to assisting you soon!