Ⅰ.Core Advantage of the Solution: Why is it a “Perfect Closed Loop”?

In traditional dredging, excavation and leveling are often performed in separate steps by different equipment, leading to issues such as low efficiency, high costs, and poor coordination. This solution leverages the versatility of the Amphibious Excavator—a true Dual-Use Excavator designed for land and water—by quickly changing attachments, allowing the same machine and the same team of operators to complete the entire process. This achieves:

- Efficient and Seamless Coordination: No downtime waiting for equipment transfer between digging and leveling; the process is continuous.

- Cost Efficiency: One machine (whether you call it a Marsh Buggy, Swamp Buggy, or Floating Excavator) performs two functions, significantly saving on equipment rental/purchase costs and labor costs.

- Controllable Quality: The same team is responsible for the entire work surface, ensuring clear accountability and higher project quality.

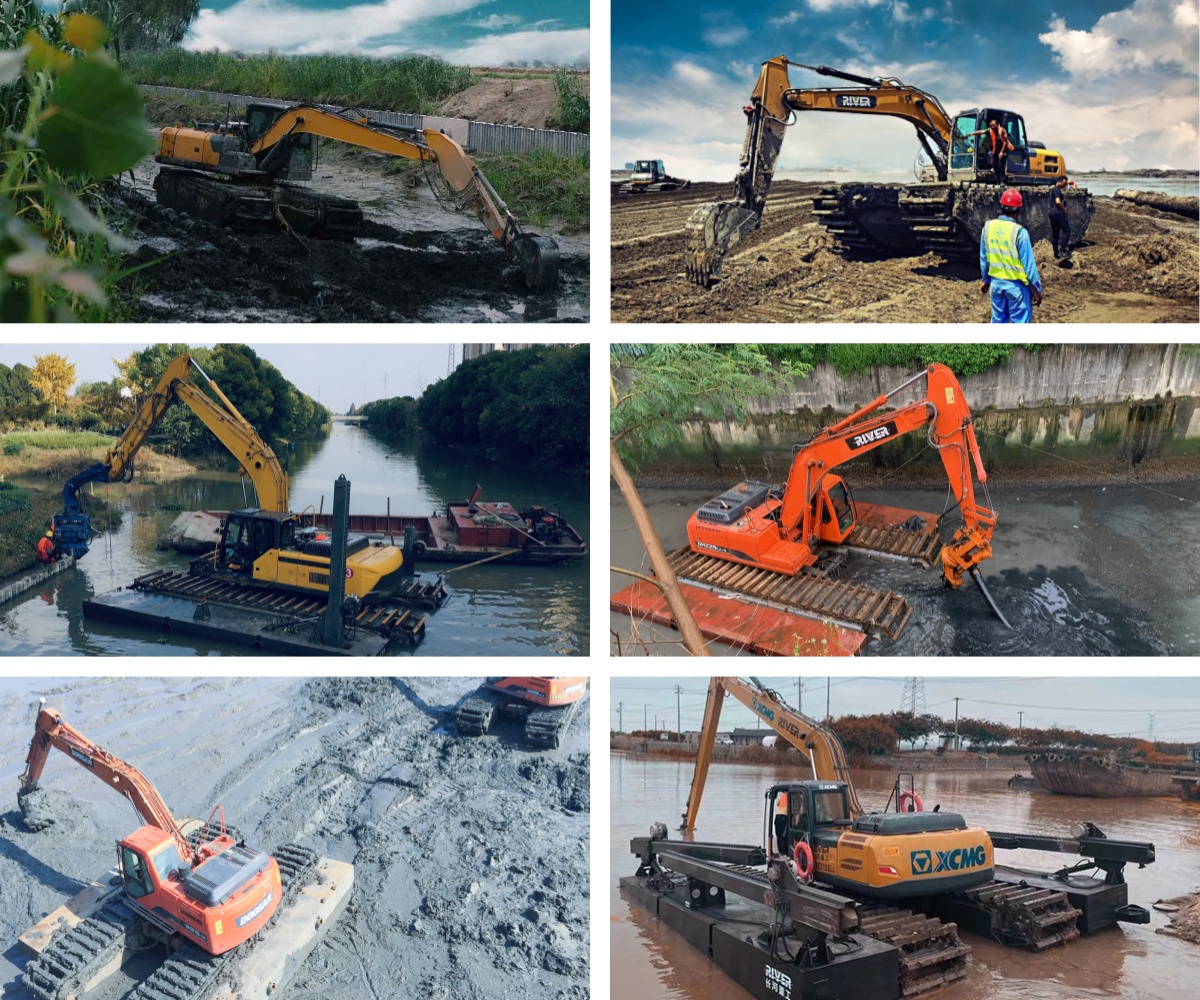

- Strong Environmental Adaptability: The Amphibious Excavator can operate in complex terrains such as shallow water, mudflats, silt areas, and slopes without dewatering or building temporary access roads, minimizing ecological disturbance. This capability is what defines it as a versatile Floating Excavator and robust Swamp Buggy.

Ⅱ.Detailed Closed-Loop Workflow

Phase One: Deep Excavation with the Dredging Bucket (Rough Digging/Main Excavation)

Objective: To quickly and remove large volumes of thick silt, sediment, and minor soft obstructions from the port waterbed.

Equipment Configuration:

Host Machine: High-power Amphibious Excavator (e.g., equipped with pontoon-style tracks ensures stability on water and low ground pressure, a key feature of this Dual-Use Excavator).

Attachment: Large-capacity rock bucket or dredging bucket (usually with teeth for easy cutting and breaking).

Operation Mode:

The Floating Excavator positions itself in a designated area and uses its long arm to extend the bucket into the waterbed.

Through the cycle of “dig-lift-swing-dump,” it lifts the silt.

The dredged material is directly loaded onto waiting barges, spoil barges, or trucks on shore.

Operation proceeds in strips and layers to ensure full coverage without excessive over-excavation.

Technical Key Points:

Adjust the digging angle and force based on the hardness of the silt.

Control the digging depth, leaving allowance (typically 10-30cm) for the fine leveling in the second phase.

Phase Two: Fine Leveling with the Rake Bucket (Precision Leveling/Base Preparation)

Objective: To precisely grade the dredged port base to the required design elevation, flatness, and slope, providing a perfect foundation for subsequent wharf construction, paving, or caisson installation.

Equipment Configuration:

Same Host Machine: The Amphibious Excavator (or Marsh Buggy).

Attachment Change: Swap the dredging bucket for a hydraulic rake bucket or leveling bucket (also called a “fine grading bucket”).

Operation Mode:

The operator uses the multiple tines of the rake bucket to repeatedly comb over the work surface like a “comb.”

Guided by sensor systems (e.g., GPS elevation system, ultrasonic depth sounder), the operator views the real-time difference between the bucket’s current position and the design elevation inside the cabin.

Precisely control the opening, closing, and lifting of the rake bucket to loosen excess material from high spots and move it to low areas, achieving “cutting high and filling low.”

After multiple passes, a smooth, level, and compact base surface is formed.

Technical Key Points:

Highly dependent on high-precision positioning and control systems, which are key to achieving “finesse.”

Operators require greater skill and patience to make micro-adjustments based on feedback data.

Forming the Closed Loop:

The process—”Excavate → Transport → Change Attachment → Fine Leveling → Inspection”—is primarily led by a single Amphibious Excavator (or Swamp Buggy), forming an internal cycle until the entire port dredging and leveling task is completed.

III. Key Technical Support

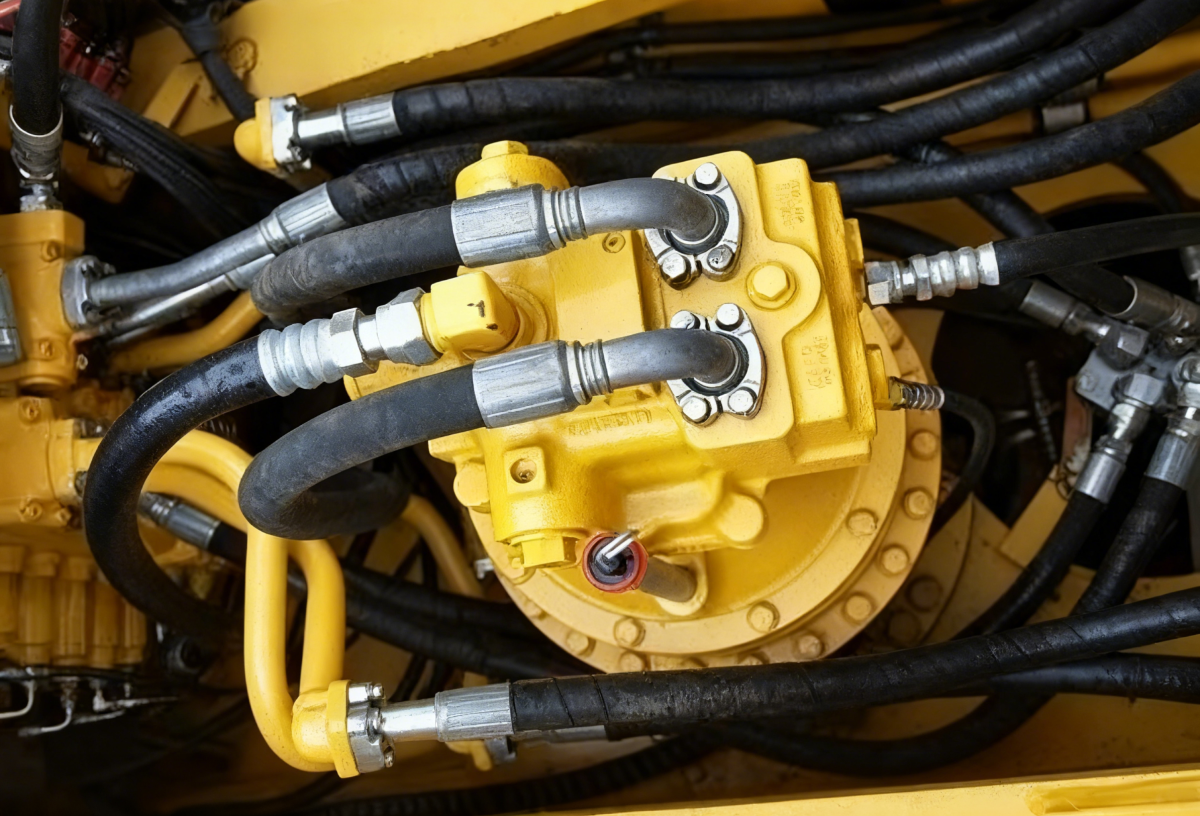

Quick Coupler: Enables rapid switching between the dredging bucket and rake bucket within minutes, a core component for improving the efficiency of the Dual-Use Excavator.

High-Precision Sensors and Guidance Systems:

- GPS Positioning System: Provides real-time planar positioning of the Floating Excavator and its bucket.

- Elevation Control System: Uses sonar depth sounding or pressure sensors to provide real-time feedback on the bucket’s elevation relative to the designed waterbed, displayed graphically in the cabin to guide the operator.

- Powerful Hydraulic System: Provides sufficient power for excavation while delivering smooth, controllable flow and pressure for fine leveling operations, essential for the demanding tasks of a Marsh Buggy.

Ⅳ.Applicable Scenarios

Maintenance dredging and base leveling for inland river ports, fishing ports, and marinas – ideal jobs for an Amphibious Excavator.

Dredging projects in shallow waters, berths, and turning basins of coastal ports where a Floating Excavator excels.

Environmental dredging and remediation of lakes, reservoirs, and navigation channels, the classic domain of the Swamp Buggy and Marsh Buggy.

Base preparation before reclamation and landfilling, a key application for the Dual-Use Excavator.

Ⅴ.Solution Summary

The closed-loop operation of the Amphibious Excavator using Dredging Bucket deep excavation + Rake Bucket fine leveling perfectly illustrates the concept of “using professional equipment for professional tasks.” It is not merely a functional addition but an integration of technology and process optimization that unifies the three major goals of efficiency, cost, and quality. It is an ideal solution for modern port dredging projects, especially for small and medium-sized ports and specific areas with higher requirements.

This solution, powered by the versatile Amphibious Excavator (in all its forms: Marsh Buggy, Swamp Buggy, Floating Excavator, Dual-Use Excavator), is particularly suitable for projects sensitive to timelines, with limited budgets, and requiring high base flatness, fully demonstrating the core value of these unique machines in aquatic civil engineering.