1.What is a Swamp Excavator and How Does It Work?

The amphibious excavator, often called a floating excavator or swamp excavator, represents vital amphibious equipment in specialized sectors like dredging and wetland construction. As versatile swamp vehicles capable of operating on land and water, their complex dual-environment nature makes proper setup and debugging more challenging than for standard dredging equipment. A meticulous pre-operation process is essential to ensure the safety and efficiency of these amphibious machines, whether you’re using a pontoon excavator for dredging excavator tasks or a marsh buggy for wetland work.

This guide provides a detailed debugging checklist and highlights seven common pitfalls to help owners, operators, and amphibious excavator manufacturers ensure their equipment—from a mini swamp buggy to a large amphibious dredger—operates reliably in demanding environments.

2.What Should You Check Before Starting the Debugging Process?

Before starting any practical operations of amphibious excavator, ensure you have read and understood the amphibious equipment operation and maintenance manual. Prepare all necessary tools and testing equipment. Safety is the top priority—ensure the debugging area is safe and organized.

3.How Do You Conduct a Thorough Land Static Inspection?

A thorough land static inspection must be completed before starting the engine of amphibious excavator. This includes:

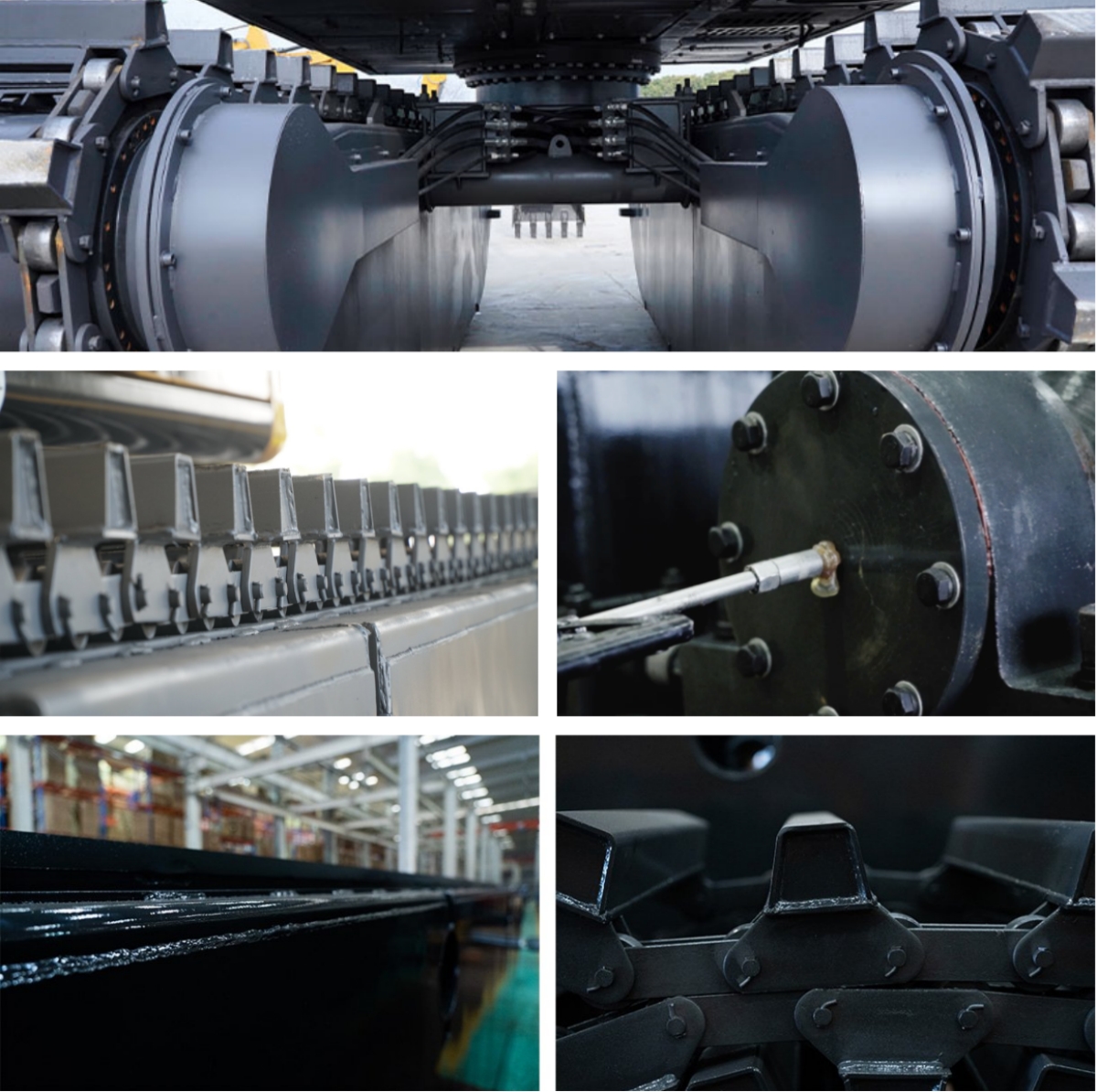

Structural Components and Welding Points of Pontoon Undercarriage: Carefully check for cracks in the welds of key structural components such as pontoons undercarriages, and swing platforms.

Travel System: Check the track tension for proper adjustment and inspect for damage to track plates and rollers.

Hydraulic System: Check the hydraulic oil level and look for leaks in hydraulic lines and connections.

Engine System: Check engine oil, coolant, and fuel levels, and ensure the air filter is clean.

4.What Are the Critical Steps for Water Adaptation Debugging?

This is the core step that distinguishes amphibious excavator debugging from conventional equipment.

Pontoon Sealing: Check that all pontoon drain plugs are tightly secured and inspect welds for signs of leakage. For the first entry into water, observe the amphibious equipment in shallow water for a period.

Watertight Compartment Inspection: Ensure the seals of critical components like the swing bearing are intact to prevent water ingress.

Propulsion and Drainage Systems: Check the flexibility of self-propellers or other propulsion devices and test the functionality of the onboard drainage pump.

5.How is the Functional Dynamic Testing Process Carried Out?

After completing static inspections, proceed with dynamic testing of swamp buggy.

Engine and Main Pump: Start the engine and listen for smooth operation. Check all instrument readings for normal indicators.

Action Testing: Operate the pilot control levers to test all movements for smoothness and coordination without jitter or abnormal noise.

Safety Devices: Test the functionality of emergency stop switches, alarms, and other safety devices.

6.Seven Common Faults and Avoidance Strategies while operating the amphibious machine

Many serious faults stem from oversights during the debugging phase. Here are seven common pitfalls and how to avoid them:

a. Pontoon Water Ingress and Corrosion

Pitfall Description: Minor cracks or poor sealing in pontoons can lead to slow water ingress, affecting buoyancy and causing internal corrosion.

Avoidance Strategies: Conduct pontoon air pressure tests; visually inspect before each water entry; drain all water from pontoons during long-term storage.

b. Deviated Movement on Water

Pitfall Description: The amphibious excavator fails to move straight on water, often due to uneven track speed or inefficient propulsion on one side.

Avoidance Strategies: Test straight-line movement in calm waters; check track tension and wear on both sides; clear debris from propulsion devices.

c. Swing Bearing Noise and Stiffness

Pitfall Description: Unusual noises or stiffness during rotation often result from failed watertight seals, allowing sediment to enter the bearing raceway.

Avoidance Strategies: Inspect the sealing lips of the swing bearing; regularly lubricate with specified grease to expel contaminants.

d. Hydraulic System Water Ingress and Emulsification

Pitfall Description: Milky hydraulic oil indicates water contamination, which can severely damage precision components.

Avoidance Strategies: Check the hydraulic tank breather; avoid replacing hydraulic components in rainy conditions; use professional oil purification equipment if emulsification is detected.

e. Electrical System Short Circuits and Failures

Pitfall Description: Damp environments can cause insulation degradation, short circuits, and system failures in electrical components.

Avoidance Strategies: Inspect waterproof seals on all electrical connections; reinforce with waterproof tape or compounds; keep the battery compartment dry and clean.

f.Entanglement with Aquatic Weeds and Debris

Pitfall Description: Tracks and propulsion systems are prone to entanglement with weeds and nets, increasing resistance and damaging components.

Avoidance Strategies: Regularly clean entangled debris; install protective guards on critical parts; plan routes to avoid debris-heavy areas.

g. Improper Transition Between Land and Water

Pitfall Description: Incorrect angles or operations during transitions can cause collisions with the bank, damaging the structure.

Avoidance Strategies: Train operators in smooth transition techniques; choose gradual slopes with solid foundations for entry/exit points; use the boom and arm for additional support.

7.Summary and Conclusion on debugging Amphibious Excavator

For amphibious excavators, “debugging” is a comprehensive process that activates and tests their “amphibious” capabilities. By following this detailed debugging checklist and remaining vigilant about the seven common pitfalls, you can effectively prevent potential losses and safety hazards.

Remember: A little extra care during debugging saves a lot of trouble on the job site. May your “amphibious warrior” forge ahead fearlessly and accomplish all its missions!